NIST researcher Mehdi Dadfarnia presented research findings based on the use of SimPROCESD software, which can model and simulate manufacturing configurations and maintenance policies for production and resource planning purposes, at the 2023 INFORMS Annual Meeting. Thousands of people attend this conference to view cutting-edge research in data analytics, management science, and operations research.

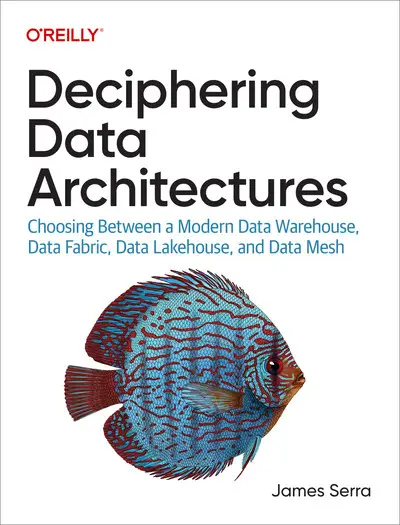

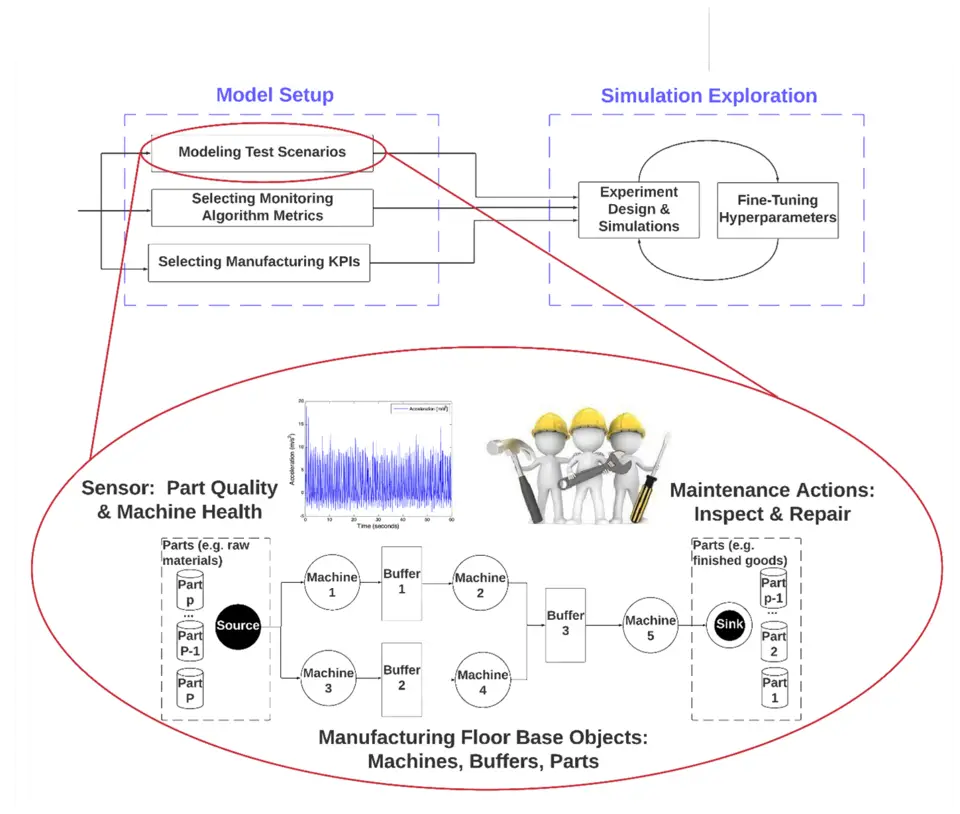

An open-source, Python-based discrete-event simulator for multistage manufacturing and equipment maintenance is called NIST softwareSimPROCESD. Users can quickly simulate and model part production in any manufacturing configuration using the software, which controls the flow of parts through manufacturing equipment to finish a job. Users can recreate a variety of maintenance actions thanks to the software’s modular design, including repairs brought on by AI-driven condition-based predictive policies, time-Based inspections, and run-to-fail corrective work.

Dadfarnia’s presentation concentrated on comparing various maintenance policies using SimPROCESD across a number of manufacturing key performance indicators (KPIs ), such as part production, machine availability, and the frequency of repair actions. The Industrial Artificial Intelligence Management and Metrology project at NIST, which develops domain-specific tools and methods to enhance the efficiency of AI systems and tools in industrial applications and to comprehend their financial and engineering risks and benefits, was the focus of this talk.